Samarium Cobalt Magnets

Samarium Cobalt Magnets

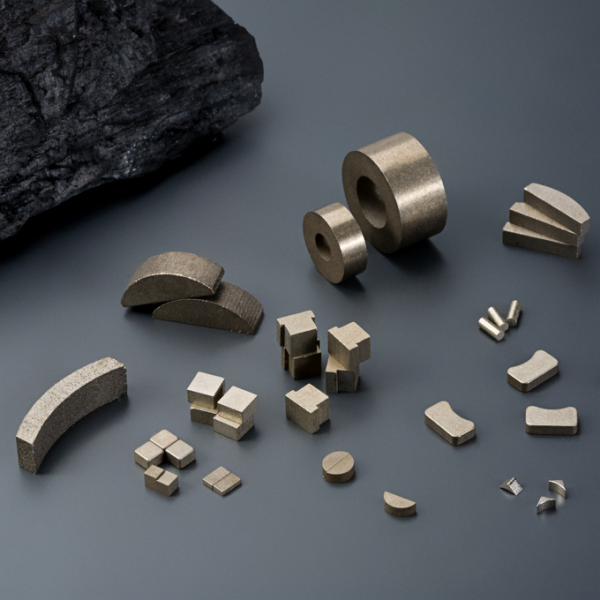

Sintered Samarium Cobalt (SmCo) magnets are a highly sophisticated magnetic material composed primarily of samarium, cobalt, and select rare earth elements. It can be categorized into two main variants based on the proportion of its constituent elements: SmCo5 and Sm2Co17. As second-generation rare earth permanent magnets, SmCo magnets stand out for its exceptional magnetic properties, combining a notably high magnetic energy product and dependable coercivity.

What truly sets SmCo apart is its remarkable temperature resilience, a characteristic that surpasses other rare earth magnetic materials. In comparison to Neodymium Iron Boron (NdFeB), SmCo magnets are particularly well-suited for operating in high-temperature environments, comfortably exceeding 200°C. Furthermore, these magnets exhibit an inherent resistance to corrosion and oxidation, often obviating the need for additional protective coatings.

Magnetic Properties

Material | Grade | Br | Hcb | Hcj | (BH)max | Tc | Tw | ||||

kGs | mT | kA/m | kOe | kA/m | kOe | KJ/m3 | MGOe | °C | °C | ||

SmCo (1:5) | SM-18 | 8.5 | 850 | 620 | 7.8 | ≥1350 | ≥17 | 145~150 | 17~19 | 750 | 250 |

SM-20 | 9.0~9.6 | 900~960 | 653~717 | 8.2~9.0 | 1194~1513 | 15~19 | 150~175 | 19~22 | 750 | 250 | |

SM-22 | 9.3~10.0 | 930~1000 | 660~772 | 8.3~9.7 | 1194~1751 | 15~22 | 159~191 | 20~24 | 750 | 250 | |

SM-24 | 9.6~10.4 | 960~1040 | 660~780 | 8.3~9.8 | 1194~1751 | 15~22 | 175~207 | 22~26 | 750 | 250 | |

SmCo (2:17) | SMG-24 | 9.5~10.2 | 950~1020 | 637~732 | 8.0~9.2 | 1433~1990 | 18~25 | 175~190 | 22~24 | 800 | 300 |

SMG-26 | 10.2~10.5 | 1020~1050 | 748~796 | 9.4~10.0 | 1433~1990 | 18~25 | 195~215 | 24~26 | 800 | 300 | |

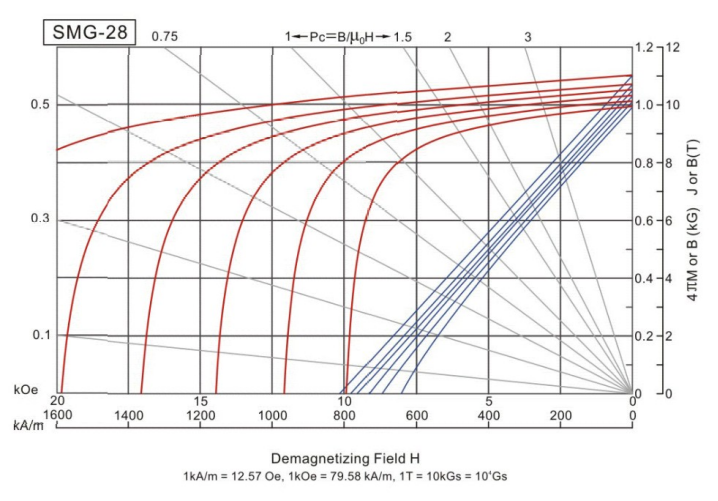

SMG-28 | 10.5~10.8 | 1050~1080 | 756~796 | 9.5~10.0 | 1433~1831 | 18~23 | 205~220 | 26~28 | 800 | 300 | |

SMG-30 | 10.7~11.2 | 1070~1120 | 677~820 | 8.5~10.3 | ≥1194 | ≥15 | 223~247 | 28~31 | 800 | 300 | |

SMG-32 | 10.9~11.5 | 1090~1150 | 677~820 | 8.5~10.3 | ≥955 | ≥12 | 238~262 | 29~32 | 800 | 300 | |

Surface Treatment

The corrosion resistance of SmCo is considered good while that of NdFeB is considered poor. Coatings for corrosion resistance are therefore not generally required for SmCo magnets. We also can offer coatings such as Ni, Zn, or Epoxy if they are used in corrosive environment.

Temperature Characteristics

SmCo magnets can operate at temperatures up to 350°C, depending upon the grade and permeance coefficient. Sm2Co17 materials exhibit superior temperature characteristics as compared to the Sm1Co5 types. SmCo magnets have extremely resistant to demagnetization, and good temperature stability (maximum use temperatures between 250 °C and 550 °C).