NdFeB Magnets

NdFeB Magnets

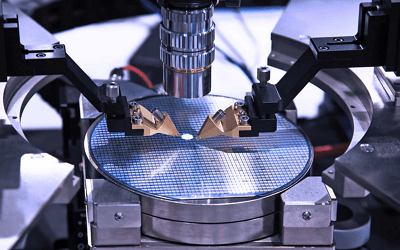

Introduced in 1983, the Sintered Neodymium Iron Boron (NdFeB) magnet stands as a remarkable innovation primarily composed of neodymium, iron, and boron. Its intrinsic coercivity far surpasses that of ferrite by a remarkable margin of 5-10 times, and exceeds aluminum-nickel-cobalt by a remarkable margin of 6-10 times. Remarkably, it boasts a maximum energy product that is a staggering 5-15 times greater than ferrite, firmly establishing it as the pinnacle of contemporary magnetic materials. In comparison with conventional magnetic materials, it not only exhibits exceptional magnetic properties but also stands out for its remarkable cost-effectiveness, thereby unlocking an extensive array of possibilities for magnetic material applications.

Neodymium magnets (also known as “NdFeB”, “Neo” or “NIB” magnets), are strong permanent magnets made from an alloy of neodymium, iron & boron. Part of the Rare-Earth magnet family, they have the highest magnetic properties of all permanent magnets. Due to their high magnetic strength and relatively low-cost, neodymium magnets are the preferred choice for many consumer, commercial, industrial and technical applications.

Magnetic Properties

Material | Grade | Br | Hcb | Hcj | (BH)max | Tc | Tw | ||||

kGs | mT | kA/m | kOe | kA/m | kOe | KJ/m3 | MGOe | °C | °C | ||

SmCo (1:5) | SM-18 | 8.5 | 850 | 620 | 7.8 | ≥1350 | ≥17 | 145~150 | 17~19 | 750 | 250 |

SM-20 | 9.0~9.6 | 900~960 | 653~717 | 8.2~9.0 | 1194~1513 | 15~19 | 150~175 | 19~22 | 750 | 250 | |

SM-22 | 9.3~10.0 | 930~1000 | 660~772 | 8.3~9.7 | 1194~1751 | 15~22 | 159~191 | 20~24 | 750 | 250 | |

SM-24 | 9.6~10.4 | 960~1040 | 660~780 | 8.3~9.8 | 1194~1751 | 15~22 | 175~207 | 22~26 | 750 | 250 | |

SmCo (2:17) | SMG-24 | 9.5~10.2 | 950~1020 | 637~732 | 8.0~9.2 | 1433~1990 | 18~25 | 175~190 | 22~24 | 800 | 300 |

SMG-26 | 10.2~10.5 | 1020~1050 | 748~796 | 9.4~10.0 | 1433~1990 | 18~25 | 195~215 | 24~26 | 800 | 300 | |

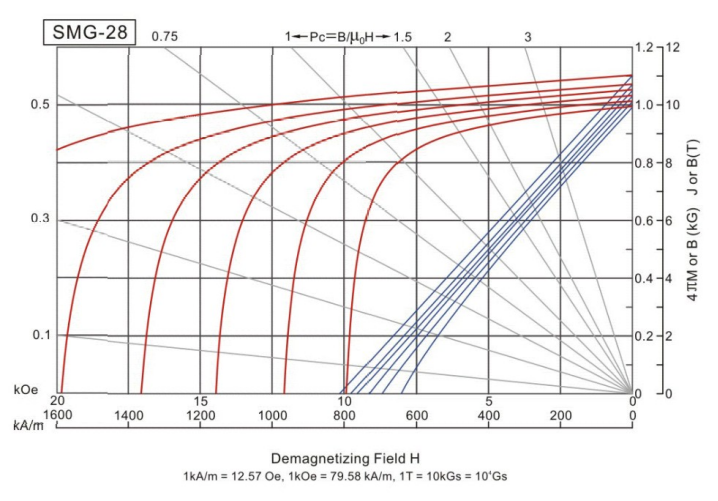

SMG-28 | 10.5~10.8 | 1050~1080 | 756~796 | 9.5~10.0 | 1433~1831 | 18~23 | 205~220 | 26~28 | 800 | 300 | |

SMG-30 | 10.7~11.2 | 1070~1120 | 677~820 | 8.5~10.3 | ≥1194 | ≥15 | 223~247 | 28~31 | 800 | 300 | |

SMG-32 | 10.9~11.5 | 1090~1150 | 677~820 | 8.5~10.3 | ≥955 | ≥12 | 238~262 | 29~32 | 800 | 300 | |

Surface Treatment

The corrosion resistance of SmCo is considered good while that of NdFeB is considered poor. Coatings for corrosion resistance are therefore not generally required for SmCo magnets. We also can offer coatings such as Ni, Zn, or Epoxy if they are used in corrosive environment.

Temperature Characteristics

SmCo magnets can operate at temperatures up to 350°C, depending upon the grade and permeance coefficient. Sm2Co17 materials exhibit superior temperature characteristics as compared to the Sm1Co5 types. SmCo magnets have extremely resistant to demagnetization, and good temperature stability (maximum use temperatures between 250 °C and 550 °C).