NdFeB Magnets

Neodymium Iron Boron (NdFeB) magnet

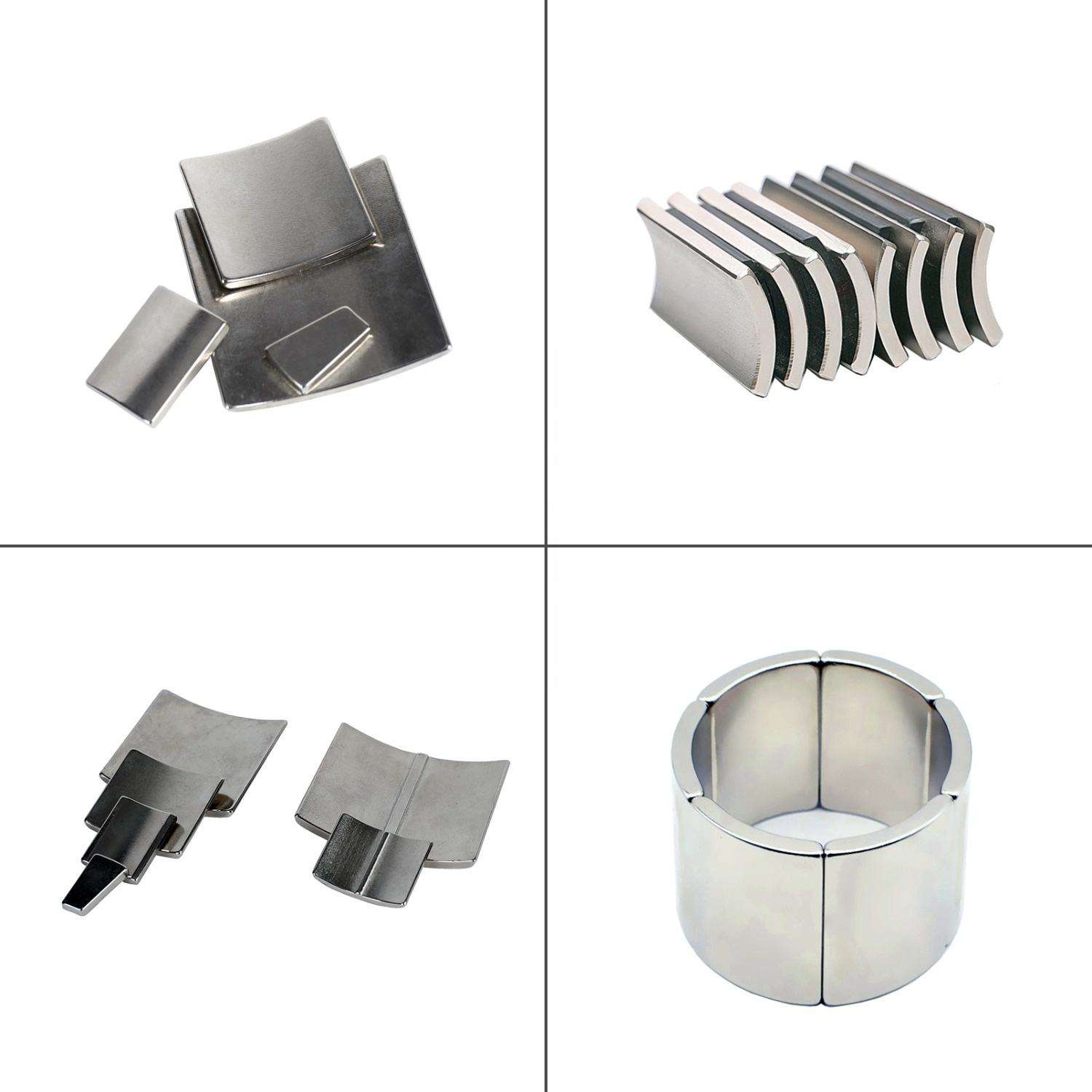

Introduced in 1983, the Sintered Neodymium Iron Boron (NdFeB) magnet stands as a remarkable innovation primarily composed of neodymium, iron, and boron. Its intrinsic coercivity far surpasses that of ferrite by a remarkable margin of 5-10 times, and exceeds aluminum-nickel-cobalt by a remarkable margin of 6-10 times. Remarkably, it boasts a maximum energy product that is a staggering 5-15 times greater than ferrite, firmly establishing it as the pinnacle of contemporary magnetic materials. In comparison with conventional magnetic materials, it not only exhibits exceptional magnetic properties but also stands out for its remarkable cost-effectiveness, thereby unlocking an extensive array of possibilities for magnetic material applications.

NdFeB Magnet Attributes

Why Choose Sintered NdFeB Magnet

Chemical Composition:Nd2Fe14B

Neodymium magnets are hard, brittle and easily corrode.

*Moderate Temperature Stability

Neodymium magnets lose -0.09~-0.13% of Br/℃. Their working stability is under 80°C for low Hcj Neodymium magnets and above 200℃ for high Hcj Neodymium magnets.

*Excellent Strength Value

The highest (BH) max reaches up to 51MGOe.

*Advanced Technology

The choice of Strip casting and HDDR technology in our factory allows us to make high performance NdFeB over N52 possible.

*Extremely Resistance to Demagnetization with Hcj

The intrinsic coercive force is over 30,000 Oe.

*Effective Surface Treatment to Prevent Corrosion

Surface treatments have been developed that allow them to be used in most applications. The treatments include gold, nickel, zinc, and tin plating and epoxy resin coating.